The process of concrete preparation and shaping requires the highest quality tools, for several reasons. Poor quality stone tools can lead to delays, unattractive work results, and replacement costs in case of a damage or other malfunction.

As a result, all elements of stone-cutting tools require attention. If even one part was picked incorrectly, it may lead to negative consequences.

Longevity, durability, convenience, and efficiency are characteristics that an average customer should pay attention to.

When it comes to price, it is not very indicative in most cases. All the stone cutting and processing tools and accessories on the market are quite expensive.

Picking a cheaper tool only because of its lower cost is to condemn yourself to problems and inefficiency in advance.

However, there are too many tools on the market. In addition, the consumer may not always understand how specifications are affecting the actual characteristics of the product.

All these factors make the choice very difficult.

These tools are of high quality, convenience and speed. By choosing one of these items, you buy a durable product with the best bang for the buck.

Otherwise, it is a matter of specifics and your personal taste.

Power Tools for Concrete Processing

Choosing a stone cutting tool is not an easy task. A poor quality tool means longer work and discomfort for the operator, who cannot be responsible for results after handling an uncomfortable or poorly functioning tool.

Concrete Diamond Grinder

There are two concrete diamond grinders on the market that combine convenience, safety and functionality with an optimal cost. It is also worth noting that the efficiency depends on the grinders collar as well as the wheel guards, and they differ in characteristics.

First, concrete diamond grinder manufactured by Metabo is an efficient, heavy-duty, and safe option.

The machine has almost commercial grade characteristics: 23 inches in length and 21.6 lbs in weight.

It has a learning curve, so it is rather recommended for experienced craftsmen.

Safety features include a rotating handle (which also improves usability), reduced vibration, and a fuse that prevents the machine from starting accidentally. And this is justified because Metabo has a serious power of 2400 watts, heavy dimensions and a blade with diamond edges.

The Metabo grinding machine is definitely a tool for professionals who appreciate safety.

However, if you rather appreciate comfort – take a look at a concrete diamond grinder manufactured by DEWALT.

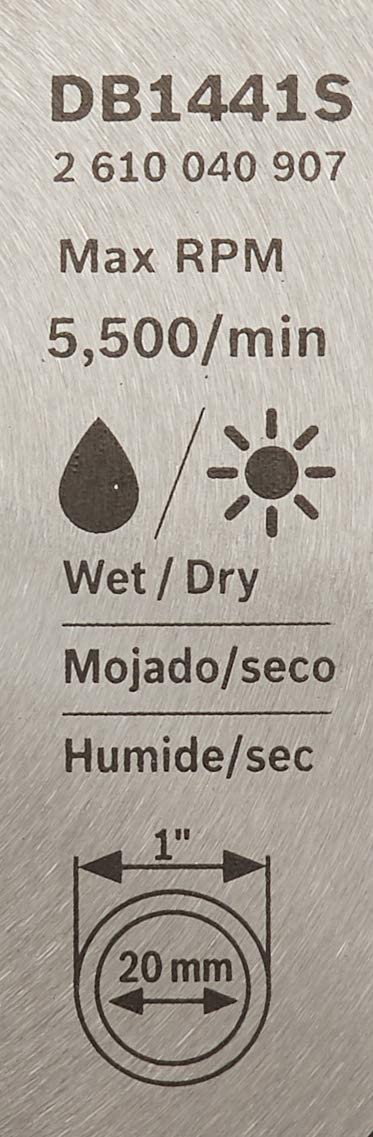

Its convenience is backed by smaller size: only 10 lbs and 17 inches in length filled with a wide variety of functions and configurations.

For example, the tool will use all its power to stop immediately in dangerous situations for itself and its owner. But this is not the main advantage of DEWALT. Its main advantage is the flexibility in approach. The concrete grinder will use needed configuration when working with different surfaces. The user can adjust the speed while working, as well as their position by rotating both the handle and the tool.The DEWALT comes with several grinding wheels or diamond cups. One, 4.5″ DW4774 has large diamond-coated and steel-coated grinding segments. The most notable feature of this cup is its durability which leads to long service.

The machine is quite powerful, so when using wheels with concentric rings on the flat surface, you’ll need to be protected from debris and excessive noise. As for dust and debris, you can enhance dust collection by making the surface wet.

According to the manufacturer, this diamond cup can endure x350 times longer than standard devices for processing stone and aggressive material removal. The DW-4774 is the smaller one of the two diamond cups suitable for purchase with a concrete diamond grinder, and weighs only 1.6 oz. This diamond cup works well with the small size of the concrete diamond grinder.

If compared with another diamond cup, the DW-4777T is slightly heavier.

The 5-inch cup weighs 1 whole pound, and has a slightly different material compared to the previous one. Though the diamond cup is not so deep, it is wider. In addition, there are more segments on its surface, and they are arranged in a way that allows the diamond cup to process the surface of concrete or other material with the most efficiency.

In terms of composition, DW-4777T cup is made of the same type of hardened steel with diamond coating on the segments. In no way this diamond cup is worse than the model above. It is just heavier and larger, but it is suitable for glass, concrete and stones.

Masonry hole saws

Masonry hole saws are made for cutting and drilling large and small holes in numerous surfaces (stone, concrete, etc).

One of the best masonry hole saws of the market is Bosch HDGM.

It is a high quality, narrow-purpose saw for working with stone. Bosch hole saw weighs 1 lb and allows you to cut holes in stone up to 1 inch deep quickly and safely.

A big advantage of the saw is its flexibility. You can separately purchase about 30 bits in different sizes, from 1 to 11 inches in diameter.

That way, with a masonry hole saw, all the holes in your home will be nearly perfect and your renovation projects will be a success without redoing problematic areas.

In addition, thanks to its design, the saw has heating control and produces fewer scattering debris.

How to select a diamond grinding wheel

The diamond grinding wheels shown below are mainly used for cutting concrete and stones. However, you will also find the ones suitable for cutting other materials: stone, asphalt, bricks, etc.

The difficulty in selecting diamond grinding wheels is that it is hard to say if it is going to be long-lasting.

Concrete diamond blades

There are three models of concrete diamond blades that are most suitable for concrete and stone work. They are different in durability, price and even weight, which is important.

Bosch concrete diamond blades come in several sizes: from 4 to 14 inches.

The optimal 12-inch blade costs about $100, weighs 2 pounds and, according to the manufacturer, can be used not only for concrete.

Like most diamond discs, it was made of tensioned steel and diamond coating.

The material and weight are indicative of long-lasting service and high quality, especially if it is used and not abused. However, the longevity of the blade mostly depends on the concrete grinder: a bad tool will destroy the disc in a matter of days.

Fortunately, this model has many sizes and fits most modern grinders. If durability is not a priority for you, the ease of replacement and maintenance is worth paying attention to.

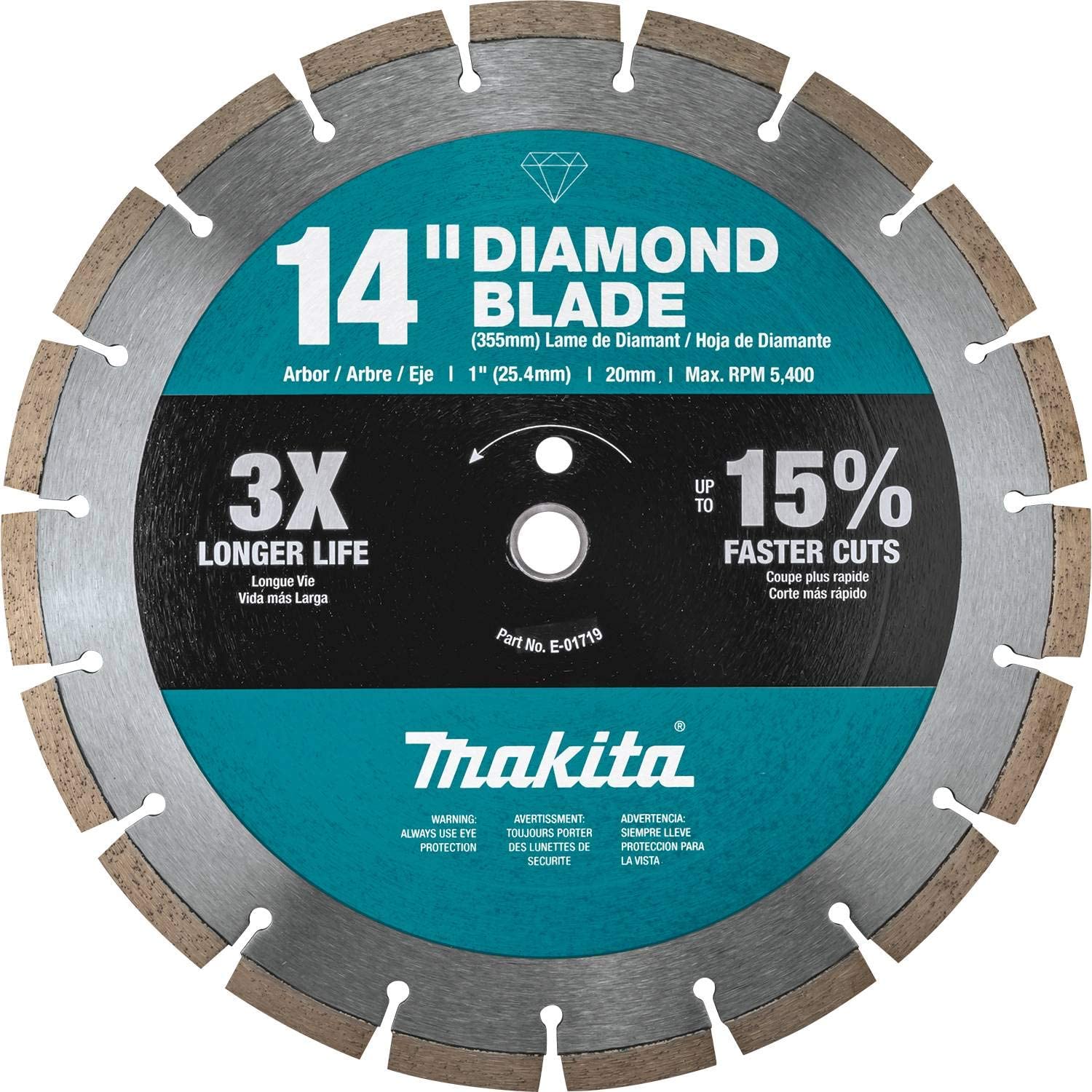

Makita disks have only one 14-inch version.

These concrete diamond blades are extremely durable and strong, since they were initially designed for gas cutters, which demands a lot of strength.

Three blades with a total weight of 13 pounds are included. The discs from Makita are heavier than usual blades. Mostly, it is made for professional use. They are not too handy to use in regular situations and are rather suitable for highly resistant materials in the most complicated applications.

If you are not a professional yet, the use of Makita discs is more likely to be excessive.

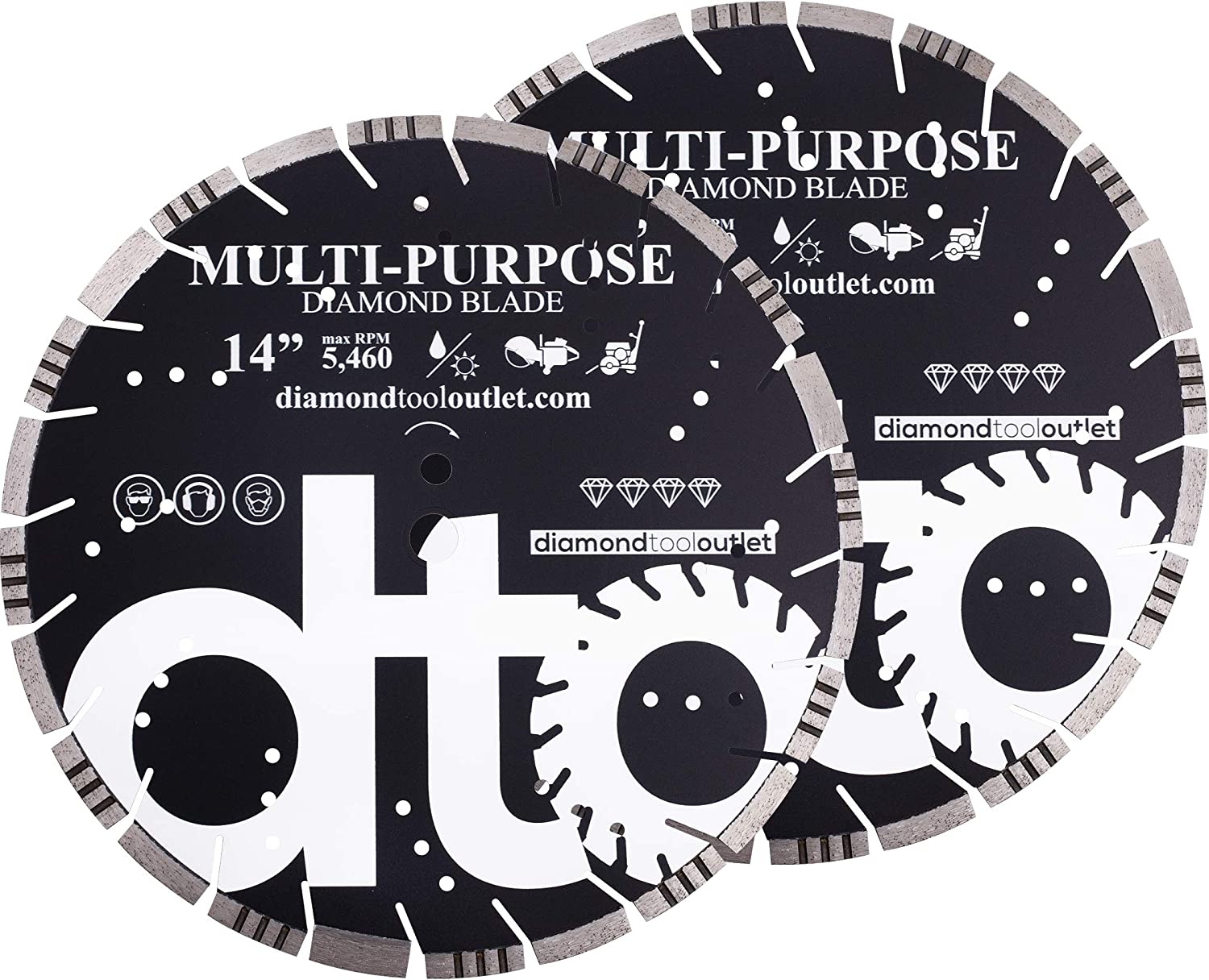

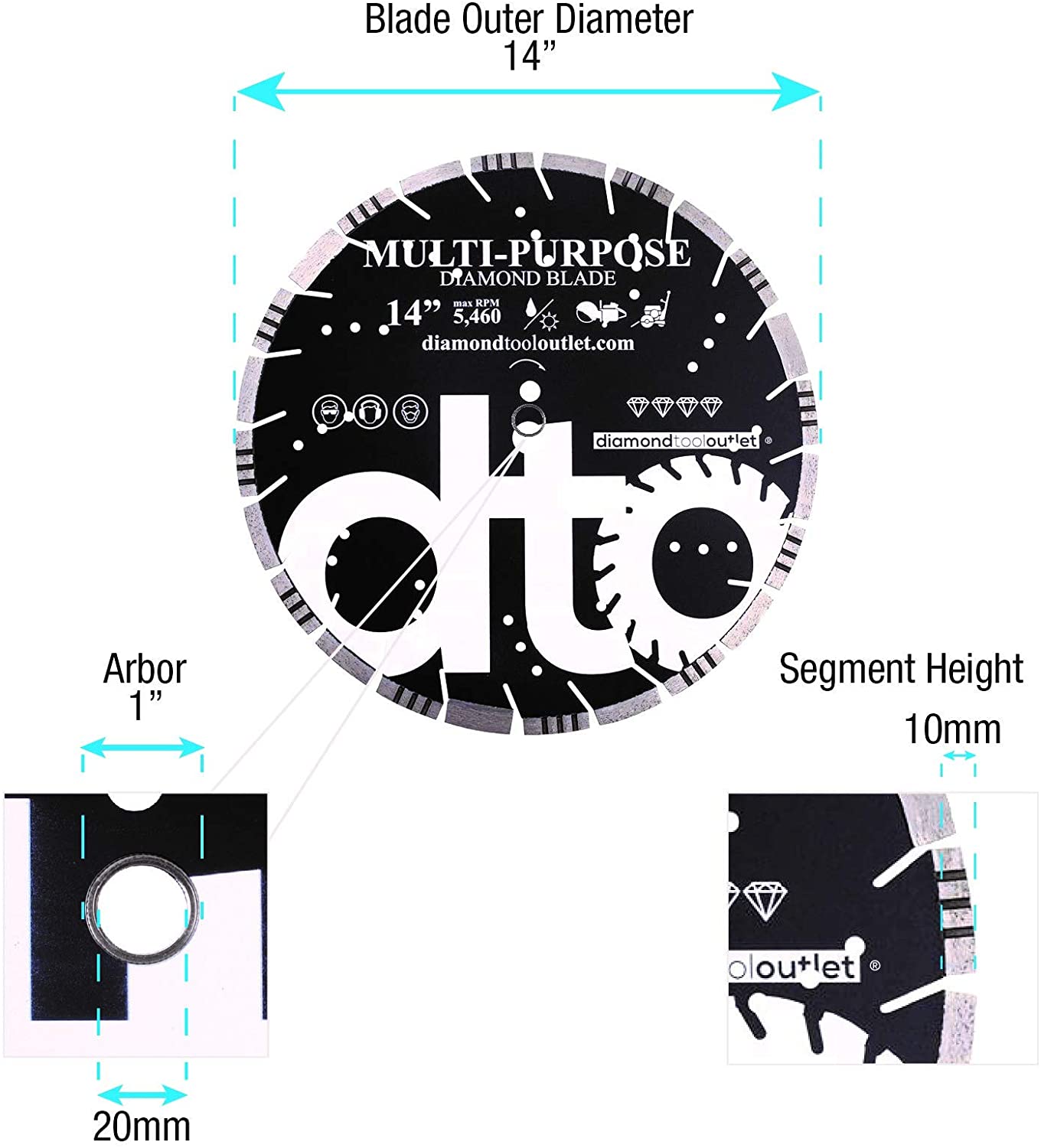

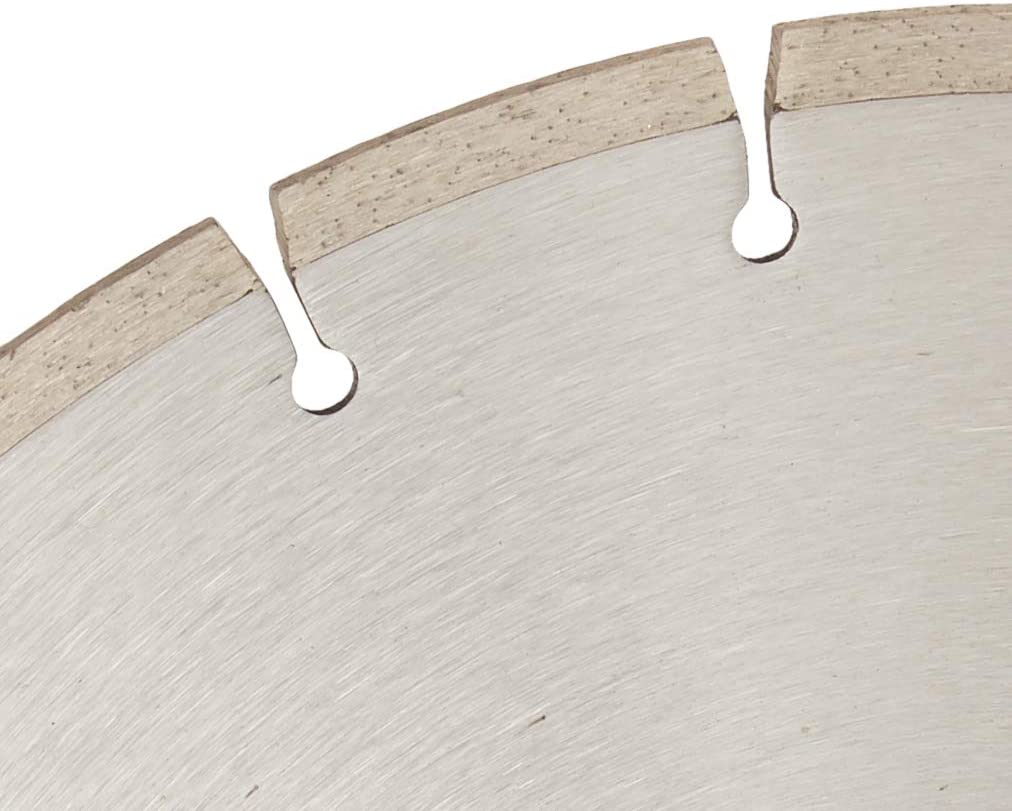

The third option is the 14-inch concrete diamond blades from dto differ rather in their versatility.

They cut through stone, concrete, bricks and many other materials like a hot knife through butter. In addition, dto discs work with almost all saws: including gas and industrial saws.

The blade was laser-melded and reinforced with a diamond. The standard blade weighs about 4.5 pounds, which is a good sign of high strength and density of the product. dto blades were also tested on many materials, proving to be one of the toughest blades on the market dealing with maximum variety of materials.

Masonry blades

From a practical point of view, this Bosch masonry blade differs from the items mentioned above, because it is lighter, less robust, less expensive and less durable.

However, due to the large size range and low price, the Bosch masonry blade is way easier to replace than a standard concrete diamond blade.

In terms of performance, the cutter works with a narrow range of materials, including stones, concrete and bricks. It works in dry and wet conditions.

The Bosch diamond blades are more affordable and light duty.

BUDGET PICK: If you are dealing with relatively soft material, there is no need to overpay – the Bosch cutters are an excellent choice backed by Bosch quality.

How to select a concrete sealant

Concrete surfaces can be considered one of the most durable and reliable. However, they are also exposed to a number of risks: temperature extremes, violation of technology in the production of concrete mix, the impact of moisture. These factors that cause the concrete to crack.

Such defects not only affect the appearance of the surface, but also carry a non-obvious danger: the penetration of moisture and an excess of liquid can provoke the destruction of concrete. Such situations must be taken into account for generic drugs storage facilities. Excessive moisture can also lead to fungus or mold.

Concrete sealants protect the material from moisture, fix annoying cracks and holes in the surface. Obviously, the sealant must be extremely durable, should be able to withstand temperature extremes and moisture.

They have a high adhesion, impermeability, resistance to water and other negative environmental effects. If you use the sealant correctly and carefully, the result will be durability and strength of your concrete work.

Diamond clear concrete sealer

I have considered three different mixtures to add some variety. Generally, they all cope with their main task – to protect the concrete surface from moisture.

The first diamond concrete sealant is produced by Euclid Chemical and contains 5 gallons of hermetic mixture.

The first advantage is the color scheme. The sealant rarely changes color, even in the sun. However, you can change the color of the sealant to the one you like or depending on the environment. Secondly, it is very strong and reliable.

Still, the sealant should be renewed regularly. However, 5 gallons will be more than enough to get you going.

The only drawback is the excessive density, which limits the range of possibilities.

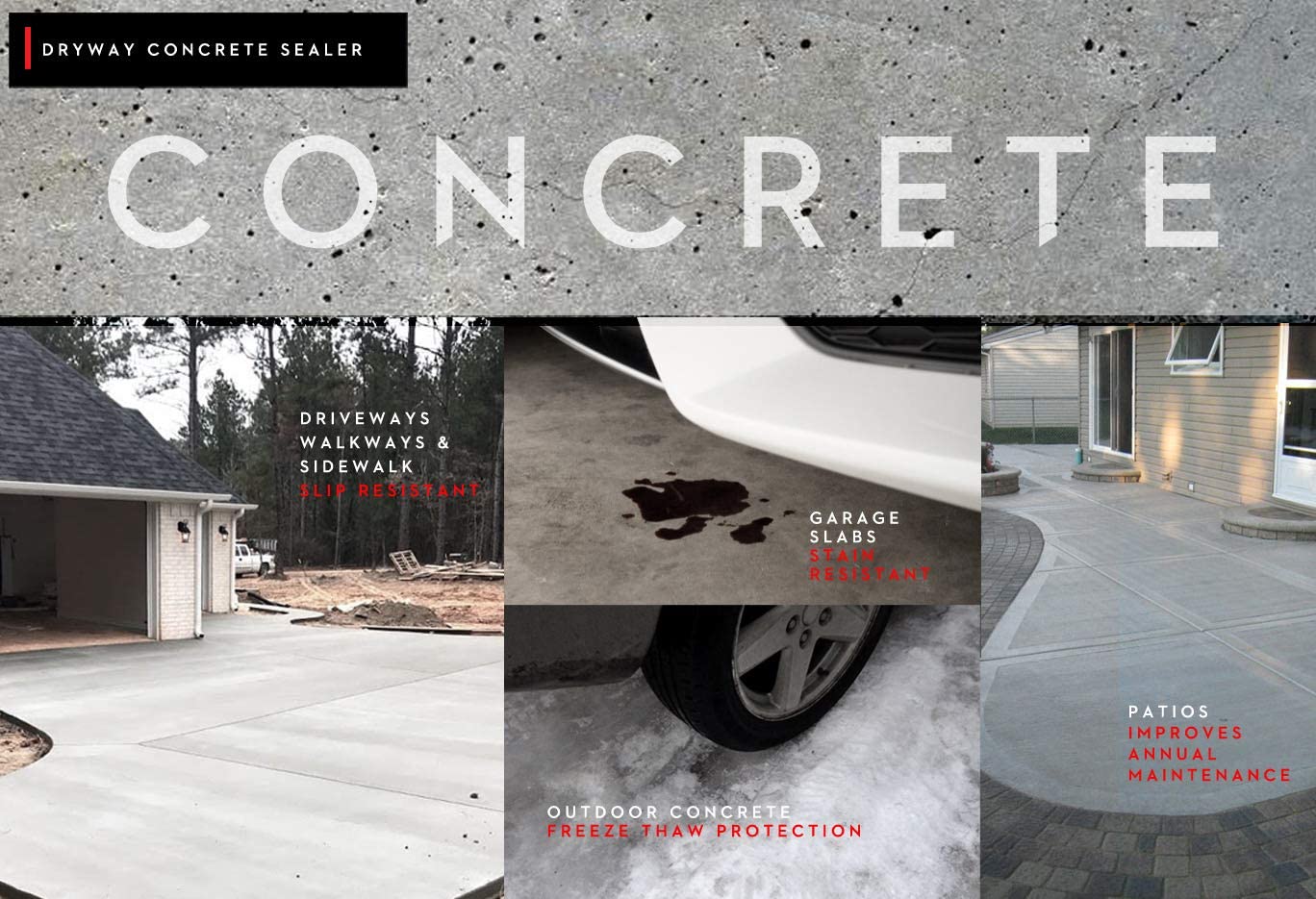

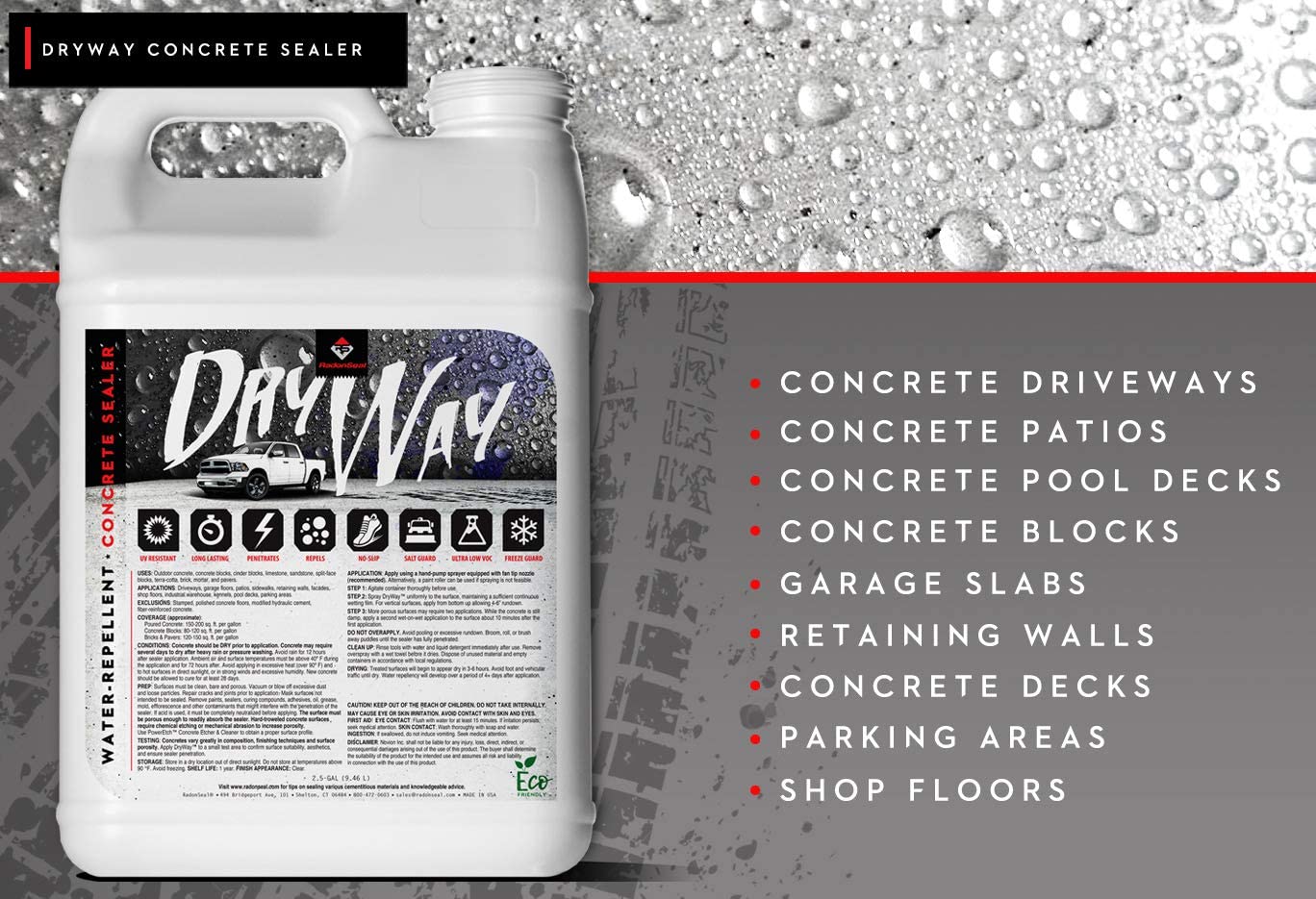

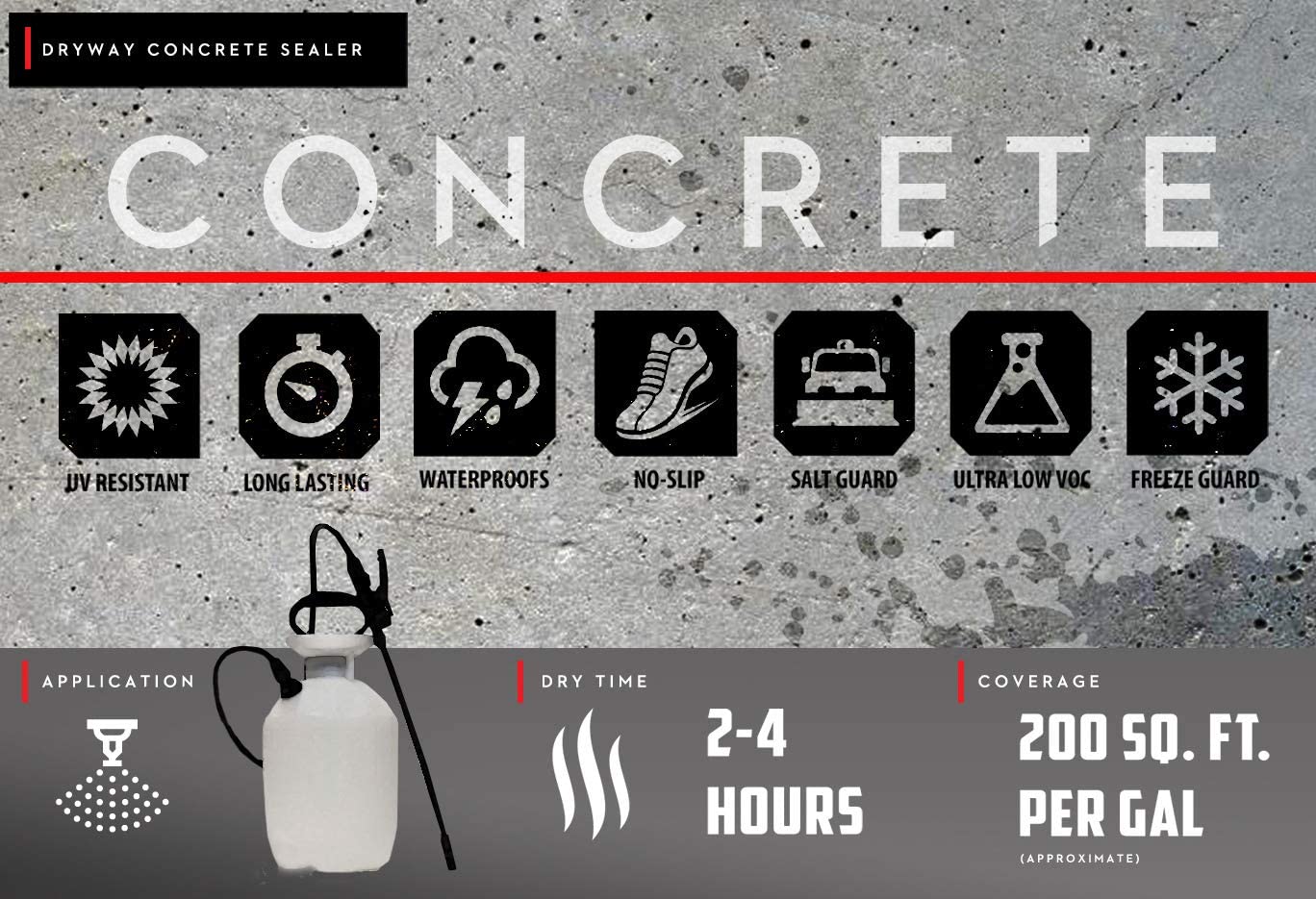

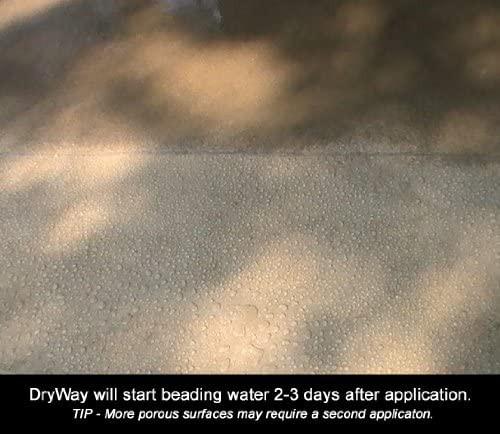

The second sealant is manufactured by Dry Way and can boast with even more advantages. It consists of silicon-related components: silane and siloxane.

It is suitable for almost all porous surfaces, including concrete, brick, paving stone and more.

5 gallons of the sealant will be sufficient for a long time, if the application is done correctly, it can last up to 7 years, so it is unlikely for you to finish an entire pack.

Though it is not the most visually appealing sealant, it ensures an increased protection from cold, liquid and salt.

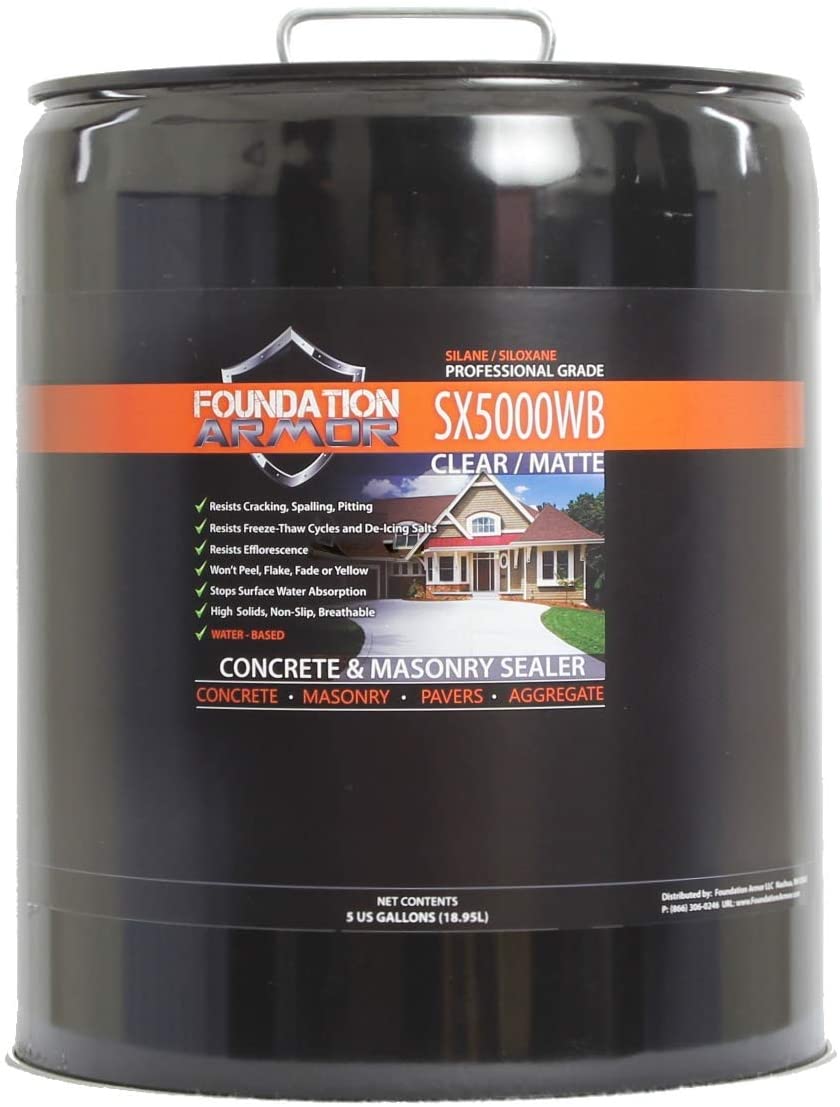

The third diamond concrete sealant is by Foundation Armor and it has the best aesthetic effect after it is applied.

The quality of this sealant is outstanding as well. The sealer was approved by the U.S. Department of Transportation hence it effectively reduces the damage caused by liquids and prevents it in the future.

As soon as you apply the sealer, it will have up to 10 years of life having the same performance. Due to its elasticity, it can be applied to all kinds of porous materials, both vertically and horizontally. The composition is based on water and consists mainly of silane and siloxane.

When choosing a concrete sealant, it is important to remember that the best option is the one that combines durability, elasticity, moisture protection and nice visual effect.

If you are interested in DIY projects and storage solutions, check out my newer articles.

P.S. REAL concrete diamond